What is the A&D AD-1688 weighing data logger?

It is a compact device designed to be connected to scales and balances made by A&D via their RS-232 interface. It stores the weight and – if required – a sequential number and the date/time. After weighing, it is connected to a USB port on a computer (just like a flash drive) to access the data:

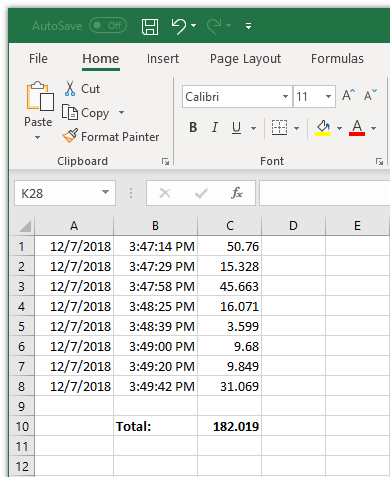

The CSV file created by the AD-1688 can be opened in applications such as Excel by simply double-clicking on it. The weight will appear as a number in its own column, ready for further processing.

Does the data logger work with scales from other manufacturers?

Sometimes, but it almost never works as well as with scales from A&D. In our tests, the following problems occurred.

Connectors and pinout

The data logger comes with suitable cables for (almost) all scales and balances made by A&D. On a DE9 connector (often erroneously called DB9), it uses pins 2 (RxD), 5 (GND) and 6 (DSR), though the latter is not strictly necessary. To connect to scales from other manufacturers, you may need adapters such as “gender changers” or null modem adapters, or you may need to make a special cable:

Please do not assume that the pinout is compatible just because the connector can be plugged in on your scale!

Possible damage

Some scales use pins of the RS-232 port for other purposes, e.g. for powering peripherals such as check weighing signal lights. These pins must not be connected to the AD-1688!

Power supply via the RS-232 interface

The AD-1688 gets its power from the scale it is connected to (or the USB port when connected to a computer). RS-232 voltage levels are clearly defined in the RS-232 standard. Nevertheless, the “RS-232” interface of some scales does not supply the voltage required to operate the AD-1688. On a Kern DE parcel scale, for example, the data logger did not turn on at all, even though the pinout matched:

Further analysis revealed that this scale did not contain an RS-232 transceiver and that logic one (“mark”) was sent as 0 V (instead of −15 to −3 V).

Interface parameters

The settings for baud rate, number of data bits and parity must match on the scale and on the data logger, otherwise the AD-1688 won’t be able to read the incoming data correctly.

When using the data logger with scales from A&D, you do not have to worry about this: Almost all A&D weighing instruments use 2400 bps, 7 data bits, parity “even”. This is also the default setting of the AD-1688.

For scales made by other manufacturers you will have to change the interface parameters either on the scale or on the data logger. The AD-1688 supports the following settings:

- Bit rate: 600, 1200, 2400, 4800, 9600, 19200.

- Data bits/parity: 7 even, 7 odd, 8 none.

Data format

The data logger expects all data to be sent as ASCII in A&D’s standard format:

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| S | T | , | + | 0 | 0 | 4 | 5 | 6 | . | 8 | 9 | g | CR | LF | ||

| 53 | 54 | 2C | 2B | 30 | 30 | 34 | 35 | 36 | 2E | 38 | 39 | 20 | 20 | 67 | 0D | 0A |

Only a very small number of scales made by other manufacturers support this exact format. If your scale sends data in a different format, two problems may occur:

- Unless each line is terminated with carriage return and line feed, the AD-1688 won’t record it.

- Even if this is the case, the numeric value of the weight will not be separated from the unit (and other characters sent by the scale).

You can generally solve the second issue by using the import wizard of your spreadsheet application. With Excel, the easiest way to open the file in the import wizard is to rename it from .CSV to .TXT.

You can try this out yourself by right-clicking here and downloading a (renamed) file we recorded on an AD-1688 connected to an Ohaus Catapult 5000 scale. This is the scale shown in the header image of this article.

Number of lines

Many scales send several line breaks after the weight (for the paper feed of a serial printer). This causes the data logger to create empty rows not containing any data. If you cannot modify the line feed configuration of your scale, you can instead increase the “Line” setting of the AD-1688 to combine several lines into one row.

This will result in empty columns (see example file above), which is much better than empty rows. However, the maximum is 7 lines. Beyond that, data will spill into the next row.

Decimal point or comma

The AD-1688 data logger cannot convert between a decimal point and comma. If you’re in a country which uses a decimal comma, this again means that you will have to use the import wizard of your spreadsheet app to correctly format the weight as a number.

Note: A&D scales let you choose whether the weight should be sent with a point or comma (e.g. “12.34″ or “12,34″) and therefore do not have this problem. You only have to ensure that the “dP” setting on the data logger matches the decimal separator used by your scale.

Transmission mode

Most scales have a “print” or “data” button to send a single weight reading to a connected device. However, this is not always the case. Some scales send the weight continuously with several values per second. This would quickly fill the memory of the AD-1688. You can mitigate this by using the “Rec” setting so that data is only stored at certain intervals, but this is far from ideal for most applications.

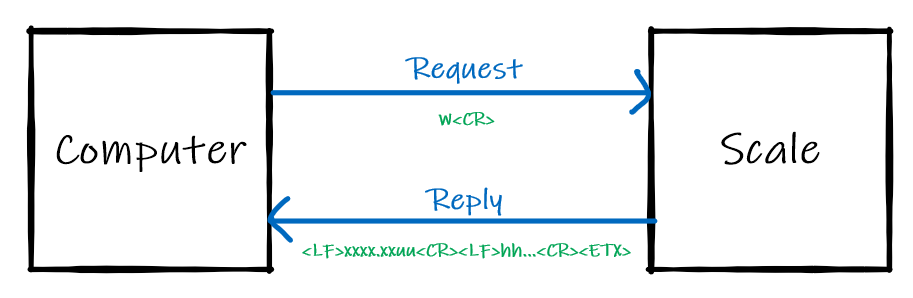

Other scales use bi-directional protocols (very common with point-of-sale scales):

Such scales can definitely not be used with the AD-1688 weighing data logger as it can only passively record incoming data. It is unable to send requests to the connected scale (see pinout above, there is no transmit pin).

Intended use according to A&D

Finally, the manual (PDF) clearly states that the AD-1688 is designed to be connected to “balances and scales with an RS-232C connector manufactured by A&D“. It was never intended to be used with weighing instruments made by other manufacturers. Given the many pitfalls described here, this is an understandable decision.

Conclusion

The trouble-free operation of the AD-1688 weighing data logger is only guaranteed with compatible scales from A&D.

On scales from other manufacturers, the AD-1688 may work, but there are many potential problems that can cost you a lot of time. Even in the best case, the resulting CSV file will often not be fully comma-separated due to differences in the data format and will require further processing.

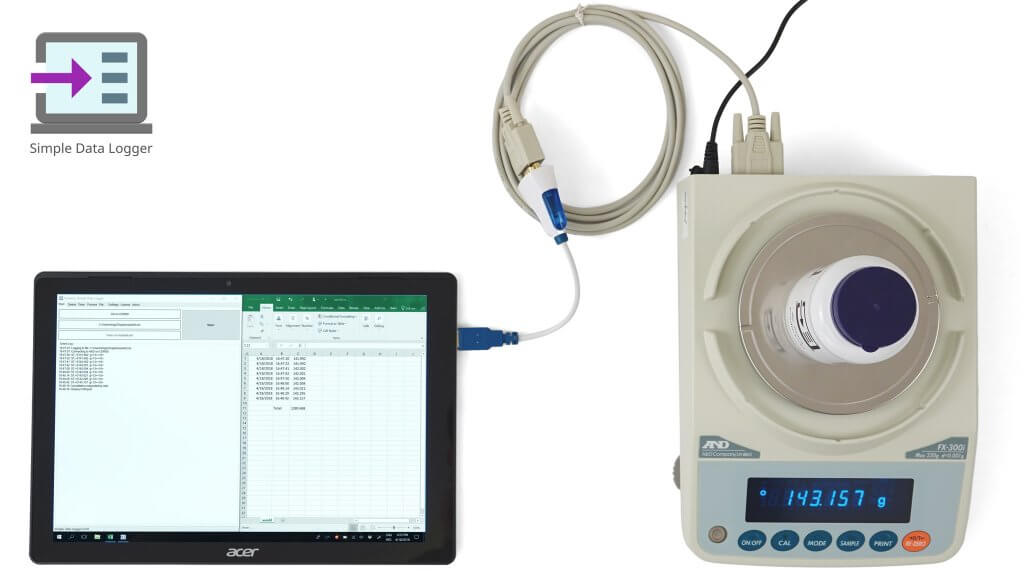

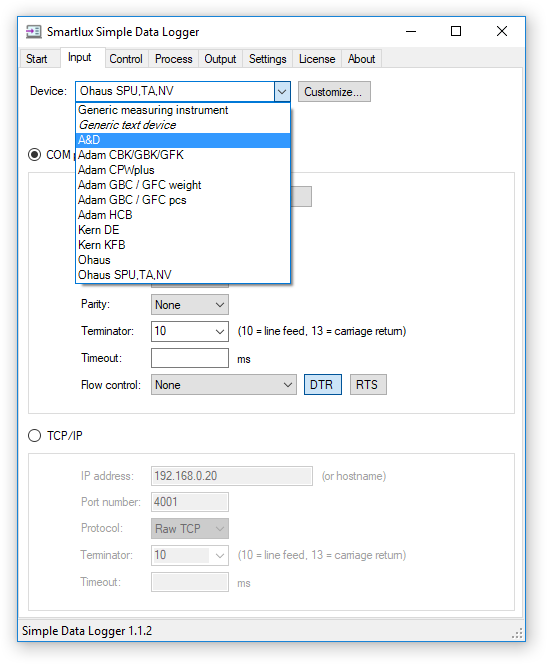

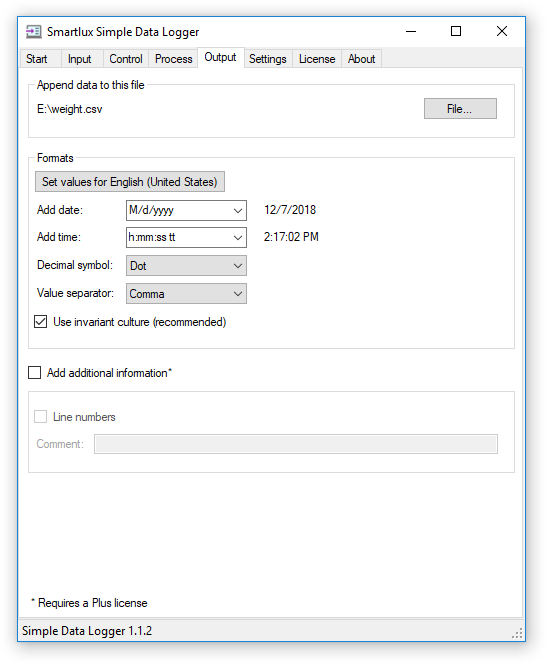

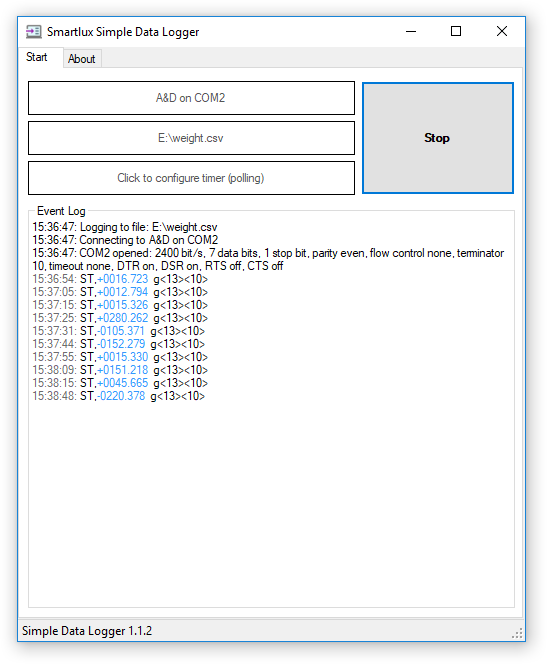

If your scale is not made by A&D, consider connecting it to a PC for data acquisition. You can use our Simple Data Logger software, which is designed to work with scales from many different manufacturers.

Note: The information in this article is valid for firmware P1.10 of the AD-1688.