RS-232 is still the most popular interface for balances and scales. It is often described as “simple”, however, when things don’t work as expected, finding the cause can be difficult.

This article does not aim to be a comprehensive RS-232 troubleshooting guide (for this purpose, please refer to this PDF document from Agilent Technologies or the troubleshooting section on our 232key website). Instead, it is supposed to raise awareness of an issue that is often ignored: counterfeit ICs.

When you’ve tried everything and still can’t reliably communicate with your scale via RS-232, there’s a chance a fake chip may be the cause.

Just a few weeks ago, the thought of encountering counterfeit ICs in digital scales had not crossed my mind. Thanks to FTDI’s recent attempt to “brick” counterfeits via Windows Update, fake chips are now a hot topic on the web. While I don’t agree with the way FTDI tried to punish the end user, I wish the controversy had occurred a few weeks earlier. This would have saved me a lot of time.

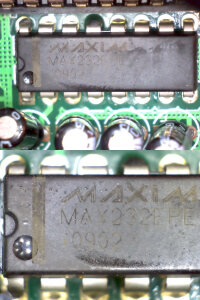

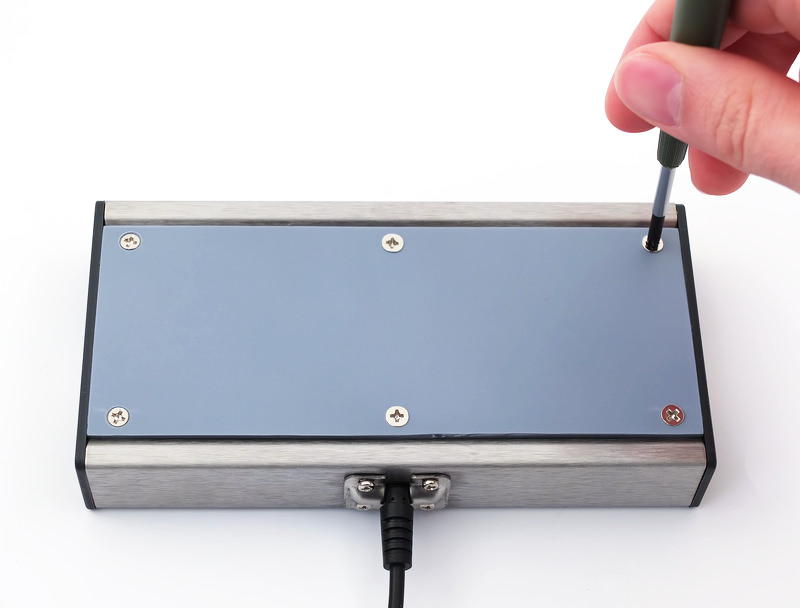

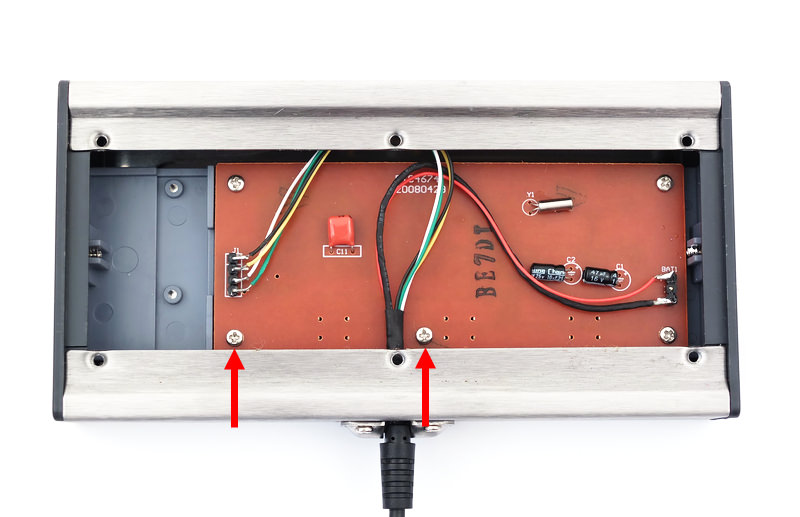

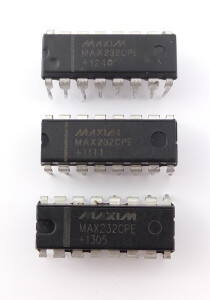

Back then I was doing the final QC for several scales which were about to be shipped to a customer. The last item on my checklist was “bidirectional communication using RS-232”, something I had done many times before with this exact model. What should have taken a few minutes ended up taking me several days and nearly drove me crazy because the problems I encountered were difficult to replicate. Eventually, I arrived at the conclusion that something was very wrong with the MAX232CPE+ chips, which are responsible for converting TTL signals to RS-232 levels. After doing some research on the internet*, I started to suspect those chips were counterfeit. It seemed like a far-fetched idea** at the time, but I still desoldered them, took a few pictures and sent them to Maxim Integrated.

Fake MAX232CPE+ and MAX232EPE+

Thankfully, I received a reply in less than two hours:

“Yes these parts are counterfeit, they do not match markings of lots we manufactured.”

Now extremely suspicious of all MAX232s***, I disassembled a few more scales from 4 different vendors. 3 contained ICs belonging to the MAX232 family, so I sent the pictures to Maxim Integrated, too. In addition to the chips used by the scale manufacturer which had prompted me to start this investigation, one chip used by another manufacturer was also flagged as counterfeit.

To be fair, my sample size is too small to draw meaningful conclusions regarding the entire weighing industry. However, if you’re in the business of making weighing instruments and were blissfully unaware of this issue, I hope this article serves as a wake-up call.

* I found documents like this one (16 MB PDF presentation by SMT Corporation) or this one (100 KB PDF, University of Conneticut), this article by Maxim Integrated and even videos of YouTubers walking through huge electronic component malls in Shenzhen where almost everything is counterfeit.

** Though not quite as far-fetched as the manufacturer’s idea that “static build up from the polystyrene packaging in road transportation” was to blame.

*** And also seriously angry at having wasted so much time doing something the manufacturer should have done. I won’t do any naming and shaming here, though.

Update October 3, 2017: Several articles concerning this issue have appeared since I originally wrote this blog post.

- Decapsulation reveals fake chips

- Investigating Fake MAX3232 TTL-to-RS-232 Chips

- De-capping ICs for fun and profit, but mostly fun

Update October 15, 2020:

- 38 minute long video about fake chips focusing on the Yamaha “YM” series of chips

- Book about fake chips published in 2015 (mentioned in the video above): Counterfeit Integrated Circuits: Detection and Avoidance (Amazon affiliate link)

Update February 13, 2022:

- 16 minute video about “The Fake Chip Scourge“