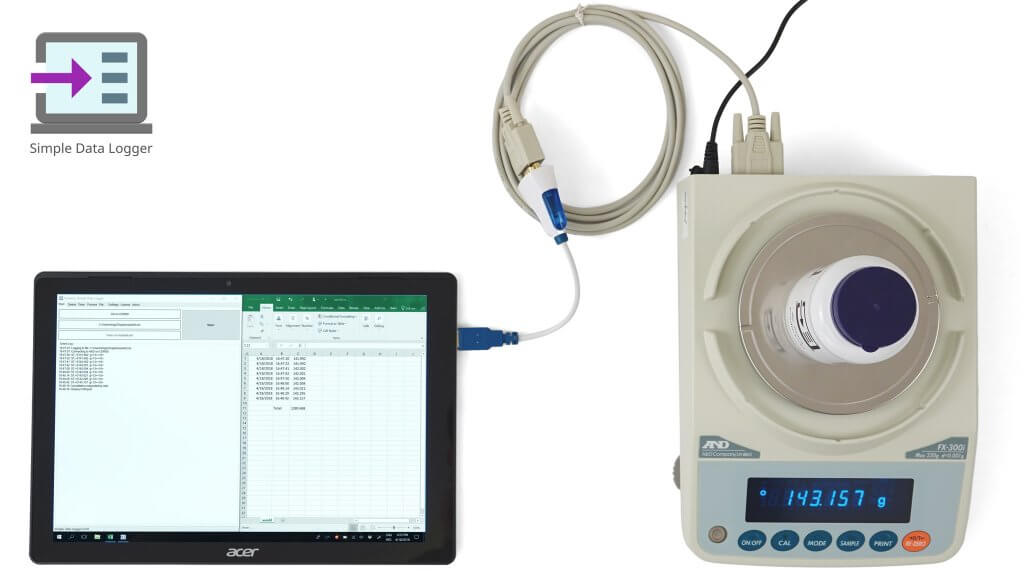

Connecting your scale to a PC and recording the weight should not be a difficult task. However, data logging software available from scale manufacturers or third parties is often expensive, difficult to use or frustratingly unreliable. We developed Simple Data Logger (SDL) to address these issues.

SDL writes the weight received from a scale or balance to a file, optionally adding the date and time. The CSV files generated by SDL can easily be opened in Excel and other spreadsheet applications for further processing and visualization.

SDL currently supports the following connections:

- COM port: RS-232, USB virtual COM port, Bluetooth SPP, etc.

- TCP/IP: Ethernet, WLAN (raw TCP format only).

Note: Your scale has to send data in ASCII format.

Get started recording weight values with Simple Data Logger

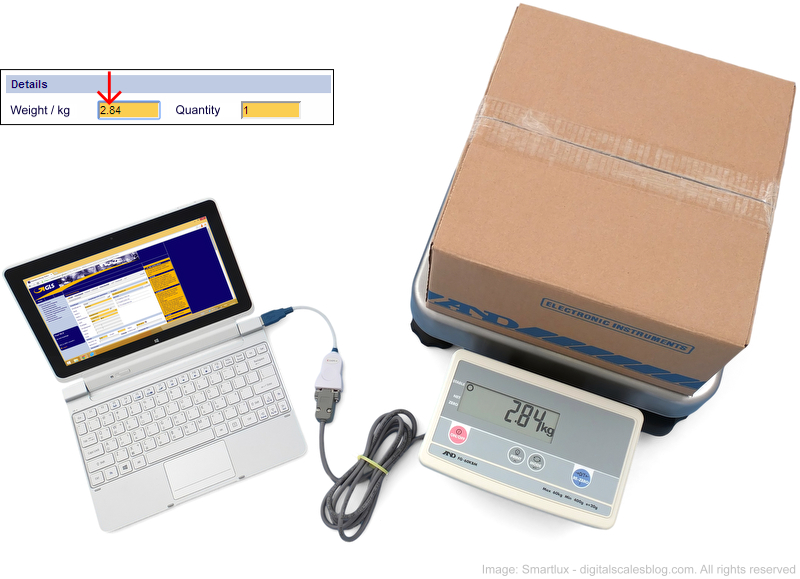

Connect your scale to your computer, download and install SDL, then follow these steps to configure the software (updated on December 7, 2019 – please refer to the documentation on the SDL website for the latest instructions):

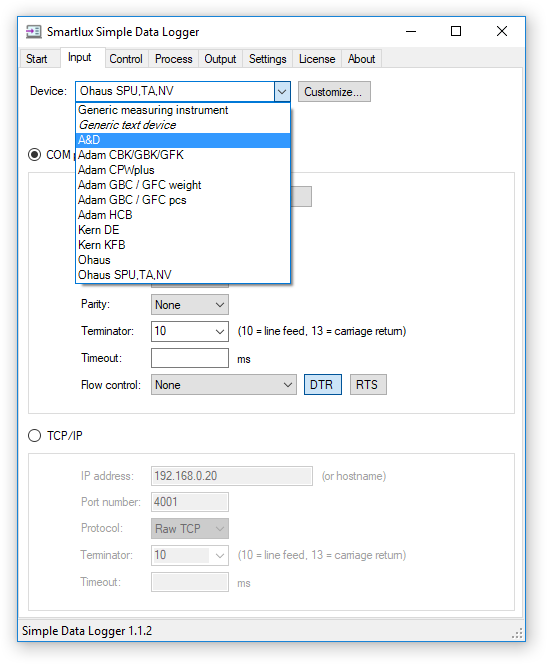

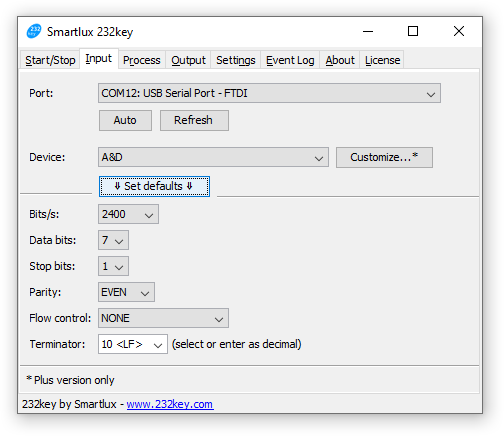

- Input tab:

If your scale or balance is listed in SDL, simply select it and press the set default parameters for device button. Otherwise, select “generic measuring instrument” and enter the interface parameters manually. Set the radio button to match your connection: COM port (RS232, USB VCP, Bluetooth SPP) or TCP/IP.Make sure that you’ve specified a terminator (a.k.a. delimiter, the last character your scale sends in each line of data) or a timeout (e.g. 100ms, SDL will process received data if no additional data is received during this time).

If your scale or balance is listed in SDL, simply select it and press the set default parameters for device button. Otherwise, select “generic measuring instrument” and enter the interface parameters manually. Set the radio button to match your connection: COM port (RS232, USB VCP, Bluetooth SPP) or TCP/IP.Make sure that you’ve specified a terminator (a.k.a. delimiter, the last character your scale sends in each line of data) or a timeout (e.g. 100ms, SDL will process received data if no additional data is received during this time). - Output tab:

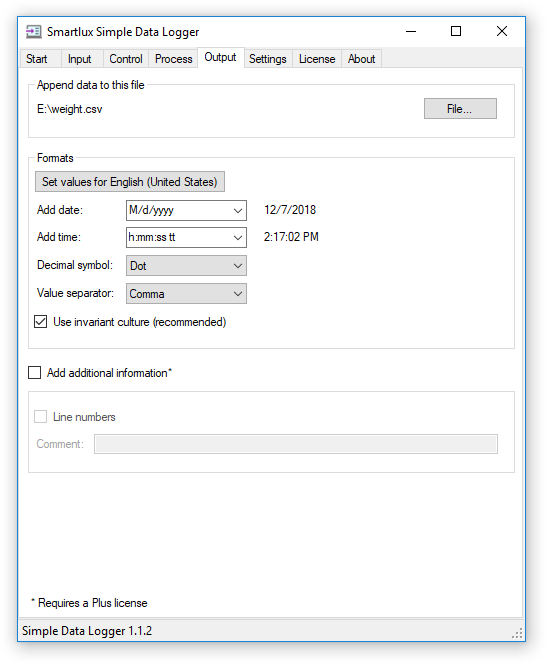

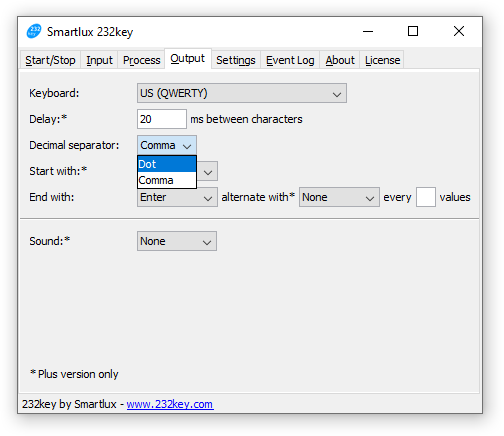

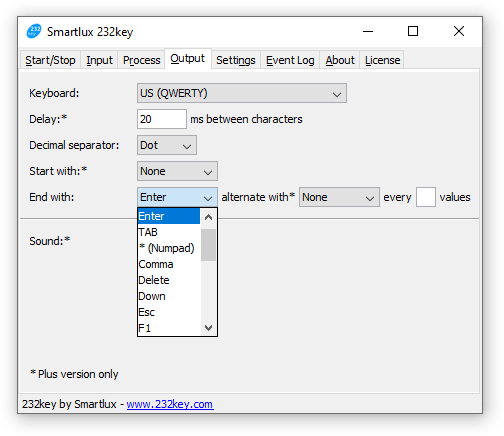

Choose a file for the recorded data. SDL will create if for you if it does not exist (otherwise, data will be appended). Choose (or enter) a date and time format or select “None” from the list if you do not want SDL to add the date or time. Pick a decimal separator (for numeric values) and value separator (used to separate values from each other). The correct settings for your locale can be made automatically by clicking on the set values button.

Choose a file for the recorded data. SDL will create if for you if it does not exist (otherwise, data will be appended). Choose (or enter) a date and time format or select “None” from the list if you do not want SDL to add the date or time. Pick a decimal separator (for numeric values) and value separator (used to separate values from each other). The correct settings for your locale can be made automatically by clicking on the set values button. - Start tab:

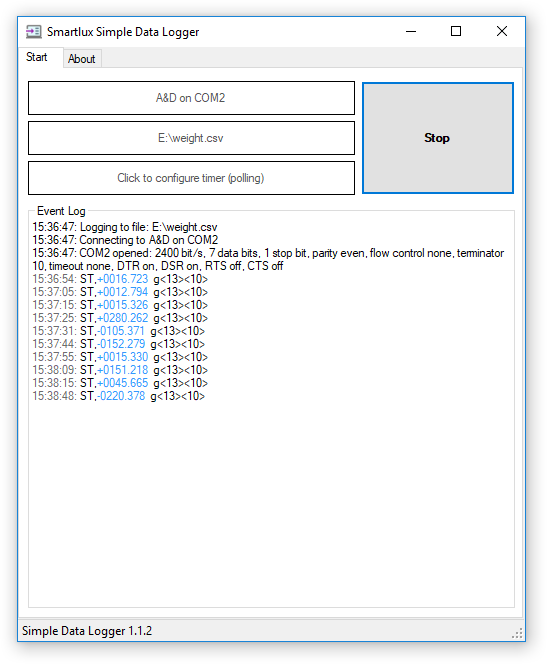

Press the start button to start recording data. Press the “PRINT” button on your scale or balance to send the weight to SDL. Depending on you scale, this button might have a different name (e.g. “DATA”). Some scales like the A&D FX-300i used in this example also have to ability to automatically transfer each (stable) weight. Data received will be shown in the event log (with the captured weight value shown in blue) and the weight will be written to the chosen file. Press stop to stop data logging and to close the file.

Press the start button to start recording data. Press the “PRINT” button on your scale or balance to send the weight to SDL. Depending on you scale, this button might have a different name (e.g. “DATA”). Some scales like the A&D FX-300i used in this example also have to ability to automatically transfer each (stable) weight. Data received will be shown in the event log (with the captured weight value shown in blue) and the weight will be written to the chosen file. Press stop to stop data logging and to close the file.Note: SDL can also handle continuous streams of weight data if this is what your application calls for (we’ve tested it with a scale which sends 100 values per second). The total number of recorded values is only limited by your disk space (but please keep in mind that Excel cannot open files containing more than 1,048,576 rows).

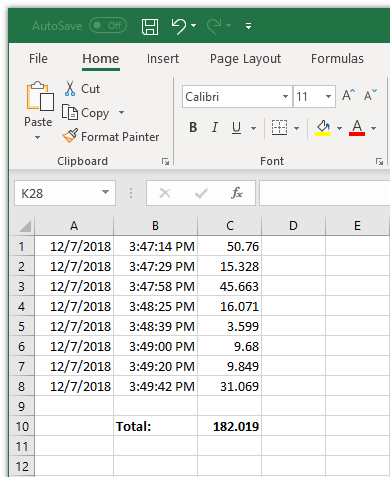

Process the weight values in Excel (or other spreadsheet applications)

Provided that you’ve made the right format settings in the output tab, you can easily open the CSV file in Excel (or other spreadsheet applications like Google Docs, OpenOffice/LibreOffice Calc). The weight will be recognized as a number, allowing you to make further calculations (i.e. calculating the total weight as shown below):

Everything shown here can be done with the “Basic” version of SDL (which is free for personal, non-commercial use). The “Plus” version has additional features including a timer to request the weight from the scale in user-defined intervals.

Everything shown here can be done with the “Basic” version of SDL (which is free for personal, non-commercial use). The “Plus” version has additional features including a timer to request the weight from the scale in user-defined intervals.

Very affordable licences can be purchased from our partner FastSpring (immediate license delivery).