“Simplifying even the most complex industrial applications” is the claim that Ohaus makes in their data sheet. Is it justified? After spending some time trying out the different functions of this scale, I believe that yes, it is.

The key to understanding the power of the Ohaus Ranger 7000 scales are the 10 application modes:

- Weighing: Determine the weight of items (no surprise here). A statistics feature can be used in weighing mode to calculate statistical data.

- Counting: Count parts of uniform weight. Auto-optimization recalculates the average piece weight as the number of pieces is increased.

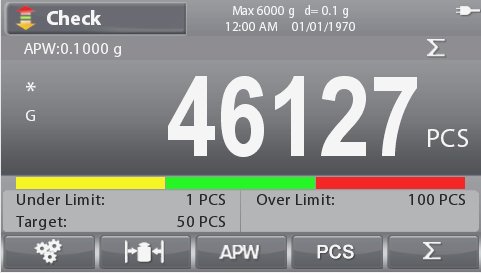

- Check weighing and check counting: Compare the weight or count of a sample against target limits. Connect with discrete I/O option kit to use external check lights.

- Formulation: For compounding and recipe making. Compensation can be used in case a component is overfilled (outside the tolerance).

- Percent weighing: Measure the weight of a sample displayed as a percentage of a pre-established reference weight.

- Filling: Fill a container to a target weight. Progress bar displays filling status. Connect with discrete I/O option kit to control a semi-automatic filling system.

- Dynamic weighing: Weigh an unstable load. Scale takes an average of weights over a period of time. Can also be used as a display hold function.

- Density Determination: Determine density of solids.

- Differential weighing: Calculate the difference between sample weights and initial weights.

- Sieve analysis: Used to assess the particle size distribution (also called gradation) of a granular material.

Each application is displayed differently on the 4.3 inch color screen. Compare, for instance, the display in weighing mode to check counting mode:

The applications are not limited to different presentations:

- Five physical smart buttons below the display take on different functions depending on the application.

- All settings relevant to the current application can be accessed easily by pressing the settings button.

- The internal library allows you to save application specific data for commonly used items (e.g. the target weight and tolerance for check weighing, the average piece weight in counting mode or the set points in filling mode). The scale can be connected to a bar code reader to simplify recalling data from the library.

- An optional I/O kit with four outputs (relays) and 2 inputs can be used to integrate the scale with external devices. The functionality is again dependent on the application mode. One of our customers has used the filling application with the I/O kit to build filling machines controlled entirely by a Ranger 7000 scale.

Therefore, as long as your application is supported by the scale, it does an excellent job at simplifying many tasks.

What is the weight limit for the Ranger 7000 scale

Up to 150 lb (60 kg), you can see the available models on the manufacturer’s website: https://us.ohaus.com/en-US/Ranger7000