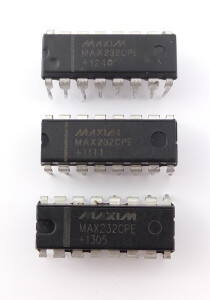

Some of the scales from A&D’s EJ series (known as “Newton” in the U.S.) can be equipped with an optional density determination kit (EJ-13), as shown in this photo provided by A&D:

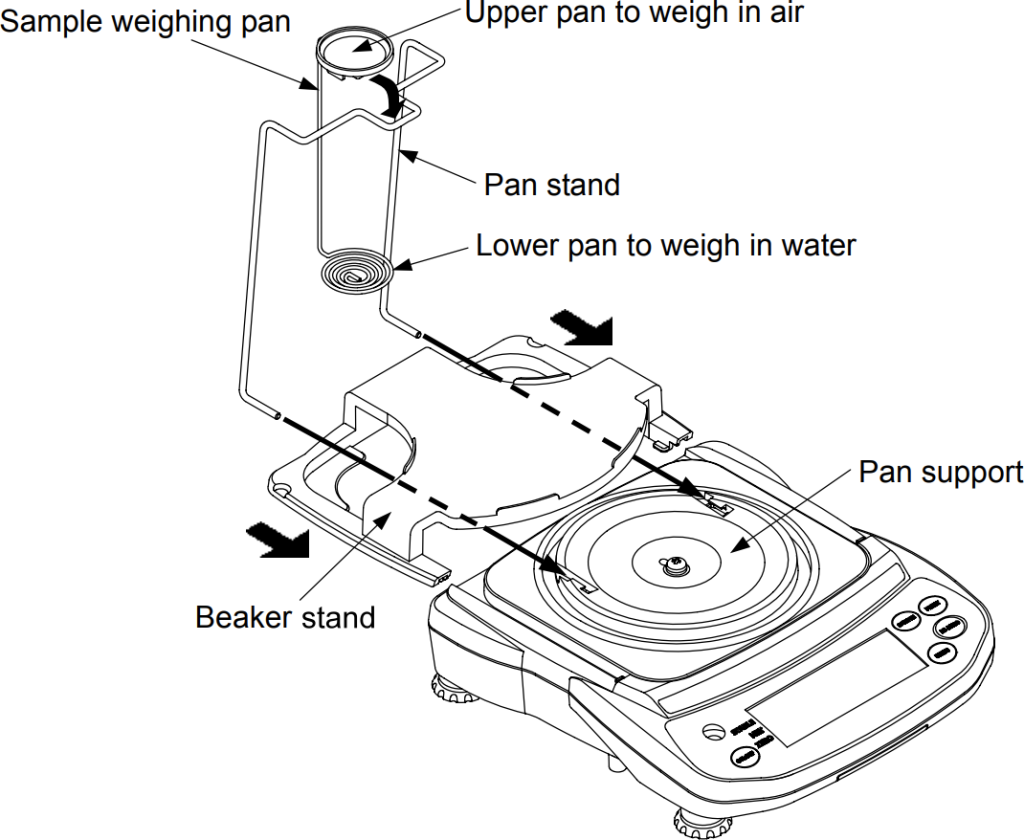

The stainless steel weighing pan supplied with the scale is removed when the density determination kit is installed. Instead, a pan stand and a special double pan are used to weigh samples in the air and in a liquid.

The problem: these two parts weigh just 38.5 g, while the stainless steel pan weighs about 55 g, a difference of 16.5 g. The manual states, “the range for power-on zero is within ±10% of the weighing capacity around the calibrated zero point.”

For the EJ-120 with a capacity of 120 g, this is only ±12 g, so we can expect a “-E” underload error when the scale is turned on. After a few seconds, it will display a negative value, which annoyingly cannot be zeroed with the RE-ZERO key.

The solution: perform a zero point calibration after installing the density determination kit (no calibration weight is required).

Note: If you have not yet purchased an EJ series scale, consider purchasing one with a higher capacity to avoid this problem.

EJ-120 scale zero point calibration

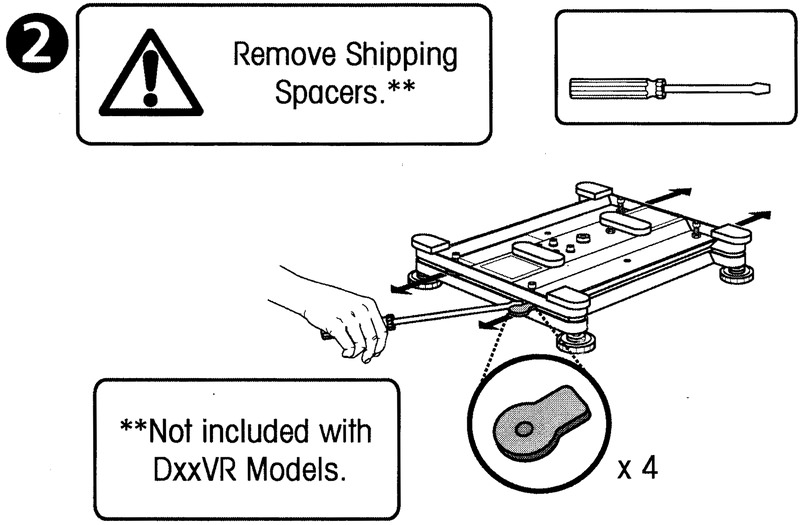

Open the calibration switch cover on the bottom of the scale:

Remove the stainless steel weighing pan and install the density determination kit as described in the manual:

Switch on the scale and wait until a value is displayed (this can take a few seconds):

Press and hold the calibration switch until the scale displays “CAL 0” (then release):

Confirm the zero point with the [PRINT] key. The scale displays “100.00” (the required calibration weight for the next step, which we will skip):

Press the [ON/OFF] key to switch off the scale.

If you now turn the scale on again, it will display “0.00 g” with the density determination kit installed.

Note: Clever readers may have noticed that the total zero range of 24 g (±12 g) exceeds the 16.5 g weight difference. Therefore, it is possible to perform a zero calibration at a point where the EJ-120 scale automatically zeroes either with the density determination kit or with the stainless steel pan installed. However, this might not work reliably for long because factors such as temperature changes affect the zero point (which is the reason that the zero range exists).

Links to the EJ series on A&D’s websites:

- Global website (only shows the high resolution models)

- US website

- European website

- Australian website